Cooling Solutions at Fusion Dynamics

Maximize Efficiency with Direct Liquid Cooling: Cutting-Edge Thermal Management for High-Performance Computing

Cooling

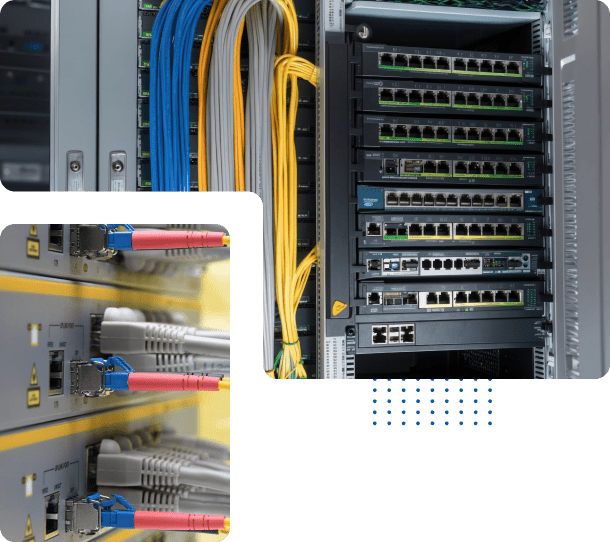

Direct Liquid Cooling (DLC) is a modern cooling technology for data centres that captures heat from server components to maximise their performance and lifetime. DLC uses a coolant liquid that flows close to heat-generating components of the chip, such as the processors, VRM, Power Supply and GPUs. The hot liquid is then pumped towards a heat exchanger that dissipates the heat, thus cooling the liquid for reflow. Using DLC, organisations can utilise their server resources efficiently and sustain optimal temperatures for server performance, hence solving complex problems more effectively.

Advantages of our Cooling product offerings

End-to-End Solution

At Fusion Dynamics , we offer a complete, closed-loop cooling system for your servers. Our cooling unit includes flow-optimised copper cold plates, best-in-class Coolant Distribution Units (CDUs) with fault-detection sensors, and DLC-enabled Rear Door Heat Exchangers that can be deployed standalone or as part of a larger DLC system.

Reliability and Performance Boost

Our DLC systems not only increase the lifetime of individual components but also allow for more reliable operation of servers by reducing failure rates. Using effective heat dissipation, they also allow for denser component packing, thereby leading to higher performance. In addition, our CDUs are equipped with sensors to monitor coolant temperature and flow rates and to detect any leakage or fault in the cooling system for seamless operations.

Overhead Reduction

With our DLC solutions, organisations can also reduce their expenses on secondary cooling systems like CRACs and chillers, and in some cases, eliminate their requirement altogether. Overall, Direct Liquid Cooling results in a space- and cost-efficient system.

Faster and Efficient Cooling

DLC dissipates heat up to 25 times faster than air cooling due to the high thermal conductivity of liquid coolants. Our copper cold plates contain carefully crafted microchannels that allow the optimal flow of liquid coolant. These compact cold plates can be mounted directly over the heat-generating components. Furthermore, our heat exchangers are rear-mounted on server racks and allow the rapid dissipation of heat close to the source. Therefore, Fusion Dynamics DLC solutions are more efficient than air cooling and thus reduce your energy costs.

Easy to Deploy and Monitor

Our DLC components can be seamlessly integrated to allow quick setup and operation of your cooling unit. In addition, the unit includes feedback sensors that enable intelligent monitoring of your cooling system, ensuring easy fault prevention and detection.